Share It

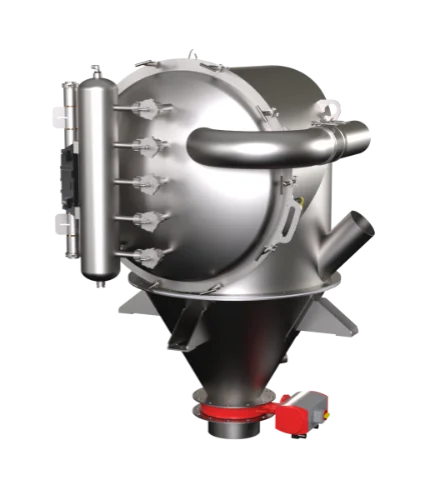

The Horizontal Filter Receiver (Moovinator) is great for facilities that have head height constraints as the bags can be removed horizontally, requiring less elevation height. It safely collects and contains bulk materials and powders. Air (pressure or vacuum) moves the material to the filter receiver where the M-HL separates dust from the convey air. Dust-free air exits the filter receiver.

M-Series products are tool free quick take apart equipment that is customized to meet your specific needs. Enjoy the peace of mind that your system will be engineered by our team. The features and benefits of the M-Series provide customers with world-class designs with customized operator-centric equipment.

Call (651) 653-5098 for Technical Information

The Horizontal Filter Receiver (Moovinator) is great for facilities that have head height constraints as the bags can be removed horizontally, requiring less elevation height. It safely collects and contains bulk materials and powders. Air (pressure or vacuum) moves the material to The Horizontal Filter Receiver where the M-HL separates dust from the conveying air. Dust-free air exits the filter receiver for industrial filtration solutions.

M-Series products are tool-free quick take-apart equipment that is customized to meet your specific needs. Enjoy the peace of mind that your system will be engineered by our team. The features and benefits of the M-Series provide customers with world-class designs with customized operator-centric equipment.

Call (651) 653-5098 for Technical Information

Whether you prefer a call or a visit, we’re ready to talk about your bulk material equipment requirements. Our team is here to assist you.