Share It

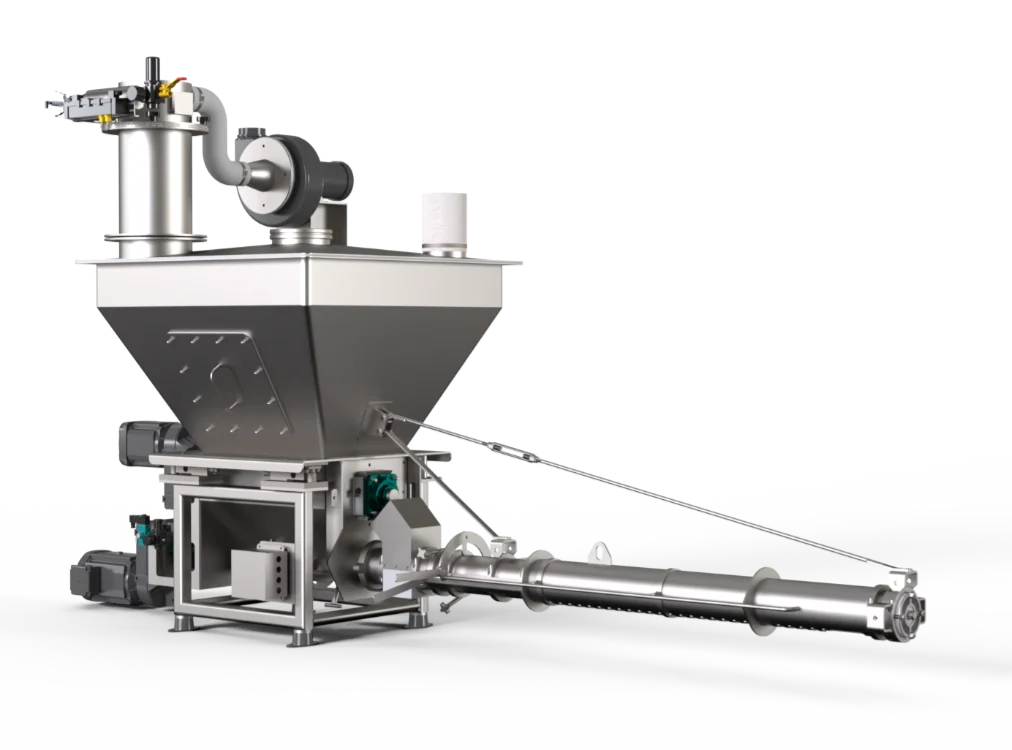

Gravimetric Enrobing Feeders are used whenever a coating needs to be added to a product and the product tumbles in a drum. For example, typical applications include adding food powders, such as salt or sugar, to a base product.

The Gravimetric Enrobing Feeder meters, spreads, and dispenses powders over a distance to create a curtain of material. HaF is flexible and can work with you on the style and design of the feeder discharge.

The accuracy of this unit occurs in two ways. First, the feeder is on load cells so the motor constantly speeds up and slows down through a Proportional Integral Derivative (PID) loop controller. Secondly, we have designed the slots with an adjustable tube so that the amount of material that dispenses at the beginning of the auger is the same as that at the end of the auger.

Included with this unit is a sample chute which serves as a catch sample where the operator can quickly calibrate and verify that the feeder is truly dispensing the rate that it is set to.

The operator sets up the feeder by setting the parameters on the Human-Machine Interface (HMI) screen and then adjusting the tube for the rate range they are running.

Call (651) 653-5098 for Technical Information

Gravimetric Enrobing Feeders are used whenever a coating needs to be added to a product and the product tumbles in a drum. For example, typical applications include adding food powders, such as salt or sugar, to a base product.

The Gravimetric Powder Enrobing Feeder meters, spreads, and dispenses over a distance to create a curtain of material, enhancing the enrobing process in various production settings. HaF is flexible and can work with you on the style and design of the feeder discharge to ensure it meets your specific coating dispenser requirements.

The accuracy of the gravimetric additive feeder occurs in two ways. First, the feeder is on load cells so the motor constantly speeds up and slows down through a Proportional Integral Derivative (PID) loop controller. Secondly, we have designed the slots of the topping applicator with an adjustable tube so that the amount of material that dispenses at the beginning of the auger is the same as that at the end of the auger.

Included with this unit is a sample chute which serves as a catch sample where the operator can quickly calibrate and verify that the feeder is truly dispensing the rate that it is set to.

The operator sets up the gravimetric powder feeder by setting the parameters on the Human-Machine Interface (HMI) screen and then adjusting the tube for the rate range they are running.

Call (651) 653-5098 for Technical Information