by: Dan Fried and Abby Cesarz

In the manufacturing sector, the threat posed by combustible dust demands a thorough approach to risk management. Central to mitigating these risks is the Dust Hazard Analysis (DHA). The DHA is a comprehensive report that details the specific hazards related to combustible dust fires, flash fires, and explosions, as well as the potential consequences of such events. A dust hazard assessment is vital for enhancing plant safety and ensuring the well-being of employees.

Identifying and Classifying Combustible Dusts

A successful Dust Hazard Analysis hinges on several criteria. The foremost of these is determining the explosive characteristics of various dusts, influenced by factors like quantity, particle size, and moisture content. Lab tests are essential to define explosibility parameters, including explosion severity, minimum ignition energy, and minimum explosible concentration. These tests help set the groundwork for implementing necessary safe manufacturing practices within the facility.

The explosibility of dust is categorized through the Dust Deflagration Index, which assigns Kst and Pmax values to measure the rate and maximum pressure of dust explosion, respectively. This index divides dust into four levels:

ST 0 – No Hazard: Powders in this category are considered non-combustible or have negligible combustibility. While they may not pose an explosion risk, other safety considerations like worker respiratory health may still be considered.

o Kst = 0 = No Explosion (Silica)

ST 1 – Low Hazard: Dusts in this category have a low explosive potential and require higher concentrations in the air to become hazardous. Proper handling and housekeeping can effectively manage the risks associated with the ST 1 materials.

o Kst = 1-200 = Weak Explosion (Powdered Milk, Charcoal, Zinc)

ST 2 – Moderate Hazard: Powders with moderate explosibility fall into this category. While the risk is higher than ST 1, effective control measures and adherence to safety protocols can still mitigate the potential for dust-related incidents.

o 201-300 = Strong Explosion (Wood Dusts)

ST 3 – High Hazard: This classification includes dust with high explosive potential. Strict safe manufacturing practices, including specialized equipment and stringent preventative maintenance, are necessary to minimize the risk of explosions.

o Kst = 301+ = Very Strong Explosion (Aluminum, Magnesium)

Key Factors for Effective Dust Hazard Analysis Implementation

An effective DHA involves a detailed assessment of the system in question, including analyzing dust types, particle sizes, concentrations, and potential ignition sources. Following National Fire Protection Association (NFPA) guidelines is crucial for identifying key safety areas.

A DHA can be conducted on-site by trained professionals who evaluate the facility’s environment, systems, and existing safety measures. Alternatively, a remote Dust Hazard Analysis might be considered, requiring facilities to provide extensive documentation of their processes and materials. However, an on-site evaluation is generally recommended for a thorough dust hazard assessment.

Supporting Safe Manufacturing Practices

Pneumatic conveying systems, widely used in manufacturing plants for moving and batching ingredients, present specific challenges related to dust explosion hazards. Integrating explosion mitigation equipment, such as vents, isolation valves, and suppression systems, is imperative for safe operations. Techniques like inerting, which involves introducing inert gases to reduce oxygen levels, are also employed to minimize the risk of dust explosions, especially with highly combustible materials.

The Role of HaF Equipment in Enhancing Dust Safety

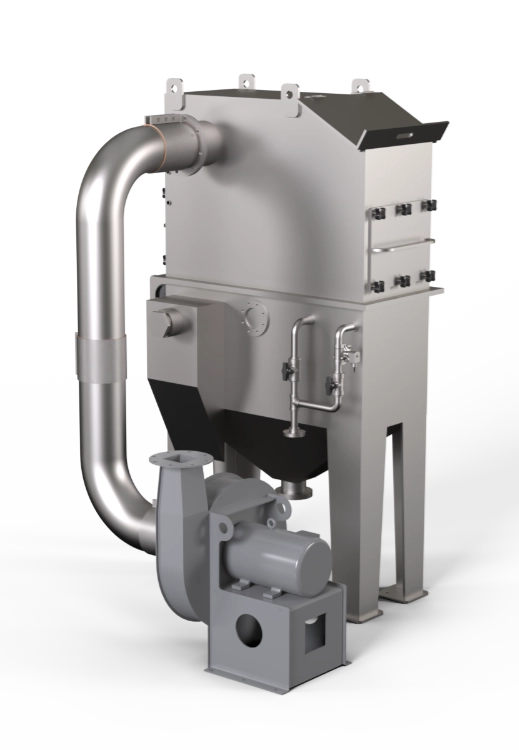

HaF Equipment utilizes and supplies many design types that help address dust explosion concerns.

One way is HaF’s innovative Jango Wet Dust collector that uses water filtration to reduce static buildup, demonstrating our commitment to improving safety in manufacturing environments. Second, by having our team help customize a dense phase pneumatic conveying system option.

Another way HaF can help is by enhancing the layout design of your system. We can assist the manufacturing facility in positioning inlets, outlets, pipes, and bin locations so that they do not risk harm to operators, maximizing the benefit of flame quenches and isolation devices. HaF can assist with designing systems that minimize the risk of a spark. We can utilize special components, including magnets, to help lower that risk.

Last, our team of engineers can design systems utilizing an inert gas. We have solutions for inert gas closed-loop systems that help save on inert gas costs, while increasing the level of safety of the system.

ABOUT HaF

HaF Equipment offers turnkey services for projects big and small. Our team understands the concerns of our customers and takes the time to listen. We develop a plan and communicate along the way. If you need someone you can trust and want to eliminate the stress of managing all the details of your next project, HaF is Ready To Connect.

CONTACT US today to discuss your next project and how our team can help from concept to system solution.