by: Dan Fried and Abby Cesarz

What is Whey Protein?

Whey protein is a complete protein derived from cow’s milk, containing all nine essential amino acids for human nutrition. It is also a valuable byproduct of the cheesemaking process. Enzymes are added to milk to separate the solid curds (used for cheese) from the liquid whey. This liquid whey is then processed to extract the protein, which is subsequently dried and often flavored for various applications.

Uses of Whey Protein in Industry

Whey protein is used extensively in the bakery and cheese production industries for several reasons:

1. Nutritional Supplements: Whey protein is a popular ingredient in dietary supplements due to its high-quality protein content and easy absorption.

2. Weight Management: In weight management products, whey protein promotes satiety and helps reduce overall calorie intake.

3. Clinical Nutrition: Whey protein is utilized in clinical nutrition to improve the health status of patients, especially the elderly, by enhancing their immune response and maintaining muscle mass.

4. Food Industry Applications: Whey protein is a versatile ingredient that enhances the texture, solubility, and shelf life of various food products such as ice creams, baked goods, and beverages.

Industry Overview

The global whey protein market is experiencing significant growth, driven by increasing health and wellness awareness and expanding applications in various sectors. North America and Europe lead the market due to their advanced health and fitness industries. Key players such as Glanbia, Nestlé, and WheyCo dominate the industry with extensive distribution networks and innovative product portfolios.

Whey Protein Production Process

1. Milk Collection and Pasteurization: Cow’s milk, containing 3.5% protein, 4% fat, and 4.6% lactose, is cooled and transported to cheese processing facilities. The milk is pasteurized to eliminate bacteria.

2. Separation: Enzymes are added to separate the milk into curds (casein) and whey. The liquid whey is then sent to protein manufacturing plants.

3. Processing: The liquid whey undergoes various treatments, including filtration and drying, to produce whey protein concentrate (WPC), which typically contains about 90% protein.

4. Flavoring and Packaging: The whey protein is flavored in high-speed blenders and packaged using specialized equipment such as dryers, mixers, and bag fillers.

Essential Whey Protein Processing Equipment

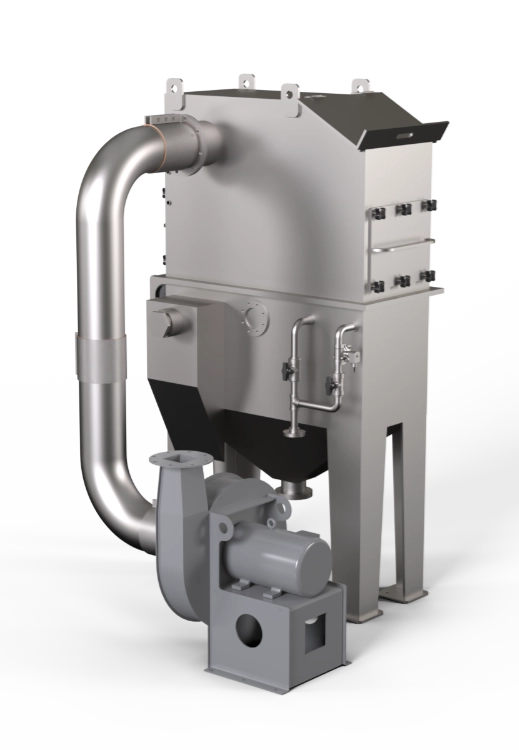

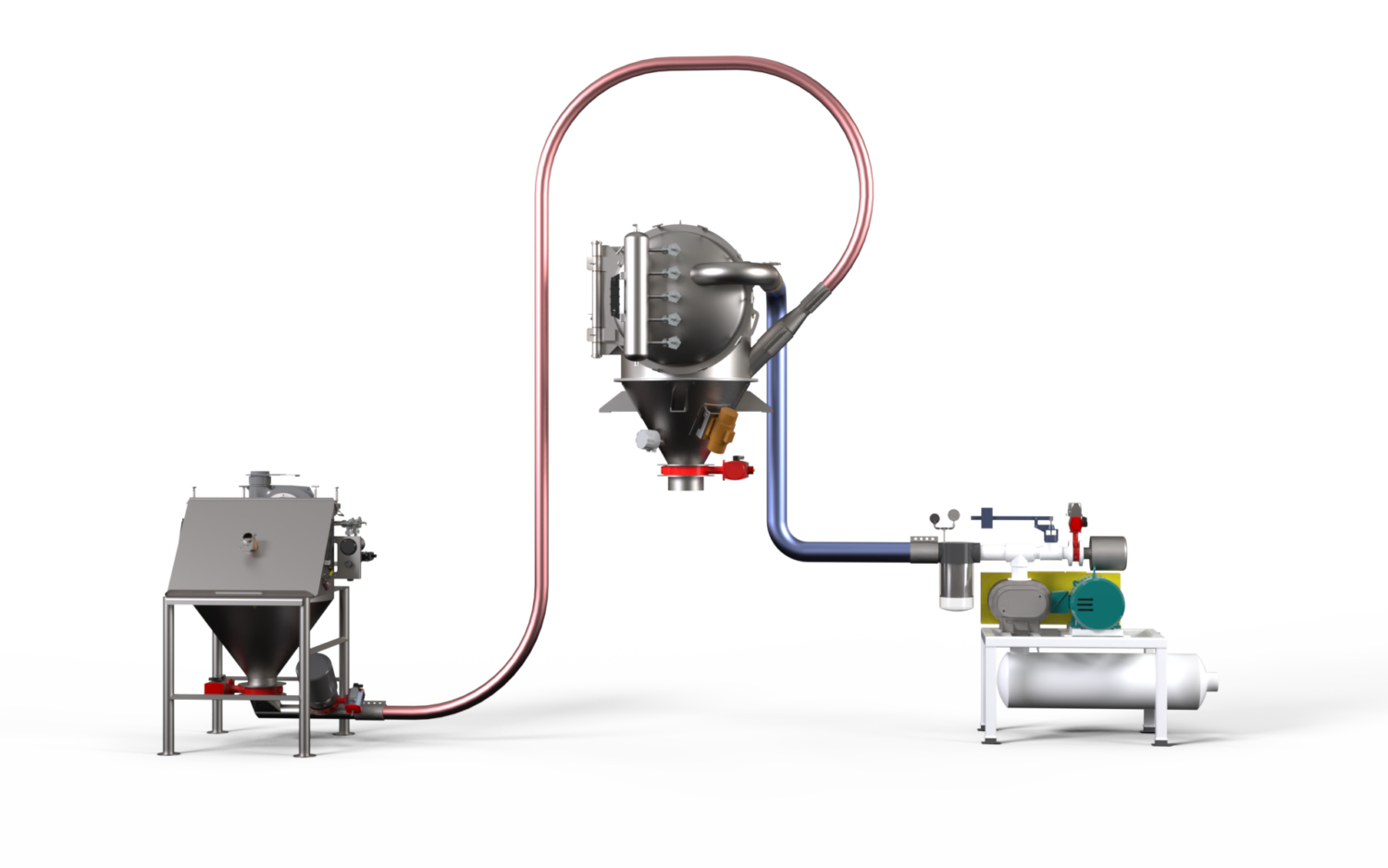

- Drying Equipment: Dryers, screws, sifters, and magnets are used to remove moisture and ensure the purity of the protein.

- Blending Equipment: Bag breakers, mixers, and airlocks are employed to blend the whey protein with flavors and other ingredients.

- Packaging Equipment: Bag fillers, scales, bag sealers, and metal detectors ensure the final product is safely and accurately packaged.

For decision-makers in the bakery and cheese production industries, investing in advanced bulk material handling equipment is essential for an efficient whey protein production process. Partnering with a reliable equipment provider ensures the quality and safety of the products and enhances operational efficiency. By leveraging the expertise and technology offered by HaF Equipment, companies can stay competitive, meet growing market demands, drive innovation in their whey protein production processes, and maintain a strong market position in the dynamic industry.

ABOUT HaF

HaF Equipment offers turnkey services for projects big and small. Our team understands the concerns of our customers and takes the time to listen. We develop a plan and communicate along the way. If you need someone you can trust and want to eliminate the stress of managing all the details of your next project, HaF is Ready To Connect.

CONTACT US today to discuss your next project and how our team can help from concept to system solution.