by: Michael Thiel and Jacob Dailey

In the manufacturing processes, the movement and management of dry powders play a pivotal role in the production lifecycle of everyday goods that we enjoy. Industries ranging from food production to high-tech manufacturing rely on the efficient transfer of ingredients like flour, sugar, and various powders such as polyethylene, aluminum oxide, or carbon black. However, the challenge lies not just in the movement but in doing so effectively, efficiently, and without compromising the integrity of the materials. Here is where the dense phase pneumatic conveying advantage becomes evident, offering a superior method that surpasses traditional mechanical, manual, and dilute phase conveying approaches.

The Quest for the Optimal Conveying Method

Traditional methods of transporting powders, such as manual handling and mechanical conveyors, often fall short in terms of efficiency, cost, and practicality, especially over longer distances. Mechanical systems, for instance, come with a high maintenance burden and can struggle with the complexities of installation across expansive manufacturing floors.

Enter pneumatic conveying, a technology that leverages air to move powders through pipelines. Pneumatic conveying can be either vacuum or pressure conveying and dilute phase or dense phase conveying.

Dense Phase Pneumatic Conveying: A Superior Approach

Dense phase pneumatic conveying emerges as a standout solution, overcoming the limitations of other methods. Characterized by its high solid-to-air ratio and lower velocity, it ensures the gentle handling of materials, significantly reducing the risk of damage or degradation. This system is particularly suited for materials with low permeability, though advancements have made it possible to convey even high-permeability materials like plastic pellets effectively.

The Engineering Behind Dense Phase Conveying

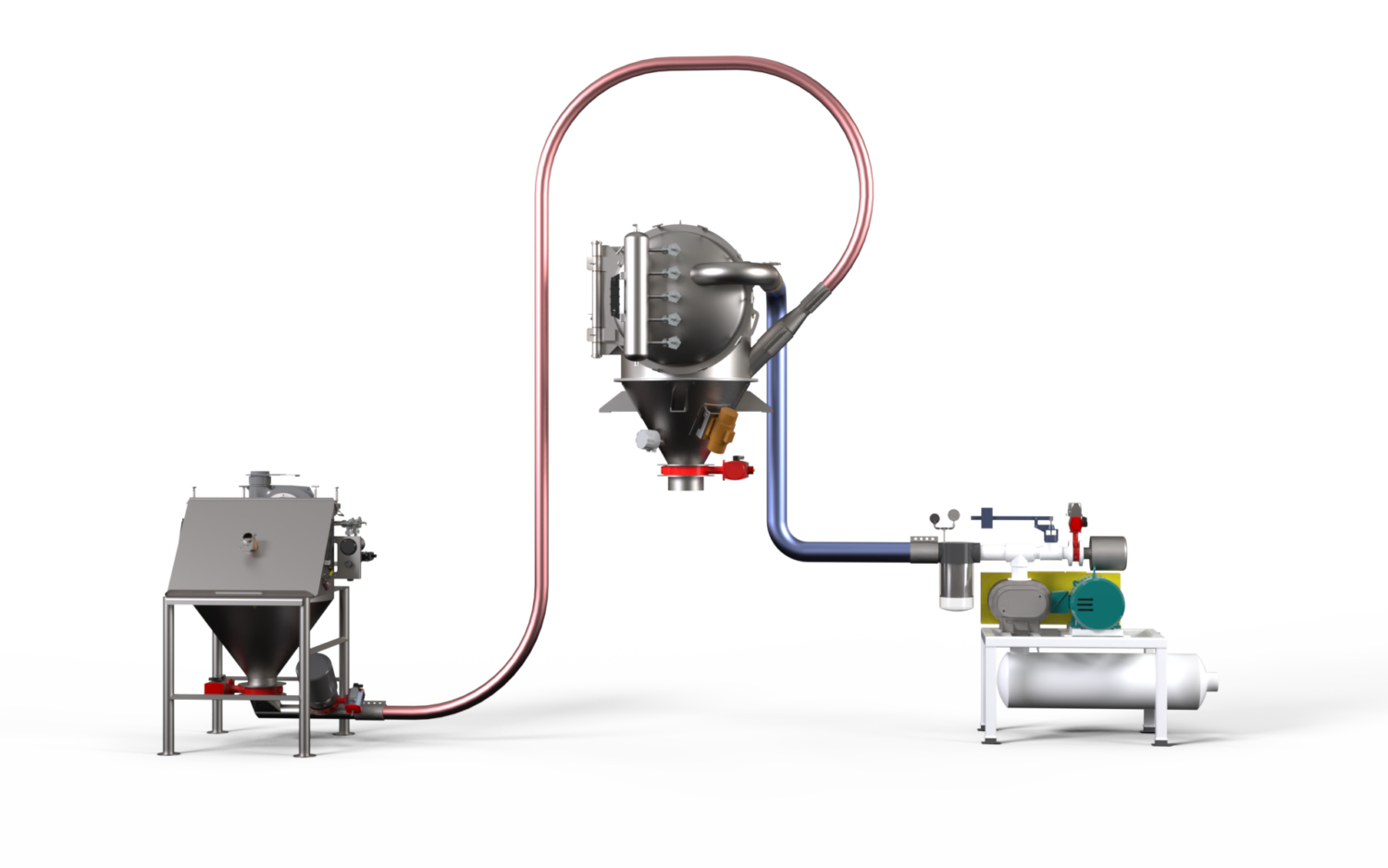

Dense Phase

Implementing a dense phase pneumatic conveying system requires a pressurized tank capable of withstanding 20-60psig, equipped with multiple air inlets and a pressure relief valve for safety. Key components include a filter receiver and, potentially, a level sensor to prevent overfilling, ensuring smooth and continuous operation.

Advantages and Considerations of Dense Phase Conveying

The benefits of opting for dense phase conveying are numerous, from eliminating mechanical parts with mechanical conveyors and simplifying maintenance to the system’s flexibility in routing and distance coverage. However, technology is not without challenges. The potential for material damage due to excessive speed or pressure within the convey line necessitates careful system design and operation.

Tailored Solutions for Diverse Needs

Beyond fragile powders, dense phase conveying is also adept at handling abrasive materials, thanks to components like the dome valve, which is designed to withstand the rigors of such applications. This flexibility underscores the technology’s versatility and applicability across a broad spectrum of industries.

HaF’s Excellence in Pneumatic Conveying Systems

In material handling and conveyance, customization and innovation are key. At HaF Equipment, we specialize in designing pneumatic conveying solutions tailored to the unique needs and challenges of manufacturers. By collaborating with experts in the field, manufacturers can enhance productivity, reduce operational costs, and achieve unparalleled product quality.

Implementing dense phase pneumatic conveying represents a strategic move toward operational excellence in manufacturing. With its combination of efficiency, gentle handling, and versatility, it stands as a testament to the power of innovation in overcoming the complexities of modern production processes to become a system of efficiency, accuracy, and customization. As industries continue to evolve, the demand for customized solutions in handling bulk materials will only grow stronger, and HaF is prepared to lead the way.

ABOUT HaF

HaF Equipment offers turnkey services for projects big and small. Our team understands the concerns of our customers and takes the time to listen. We develop a plan and communicate along the way. If you need someone you can trust and want to eliminate the stress of managing all the details of your next project, HaF is Ready To Connect.

CONTACT US today to discuss your next project and how our team can help from concept to system solution.