by: Jared Beaupre

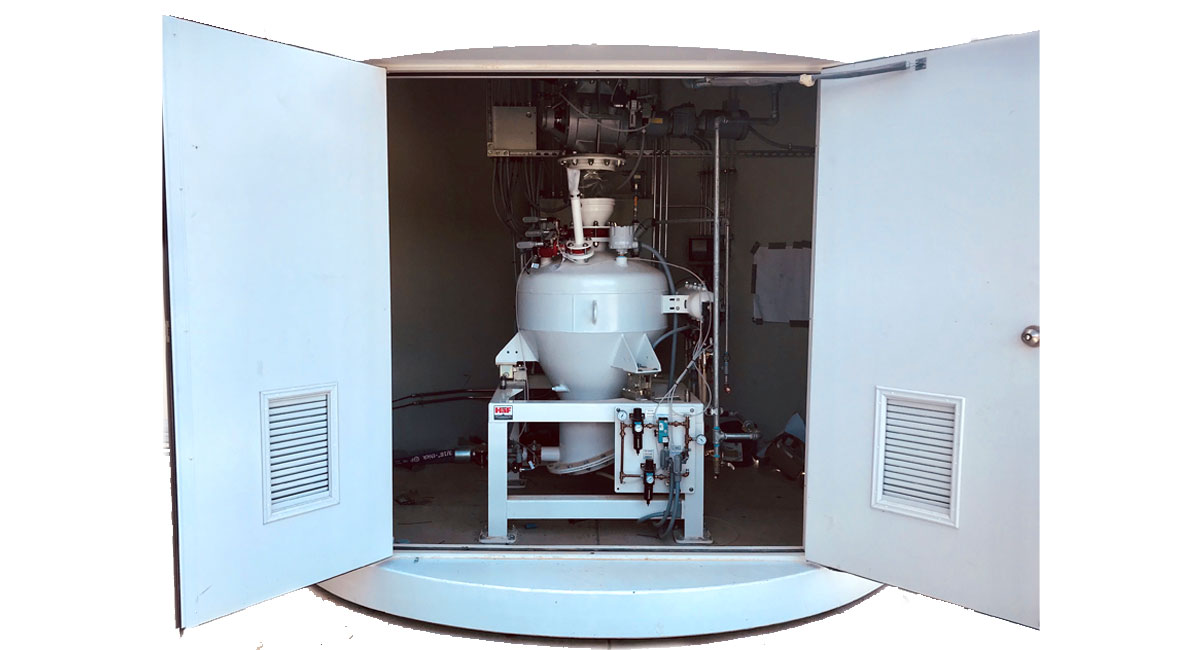

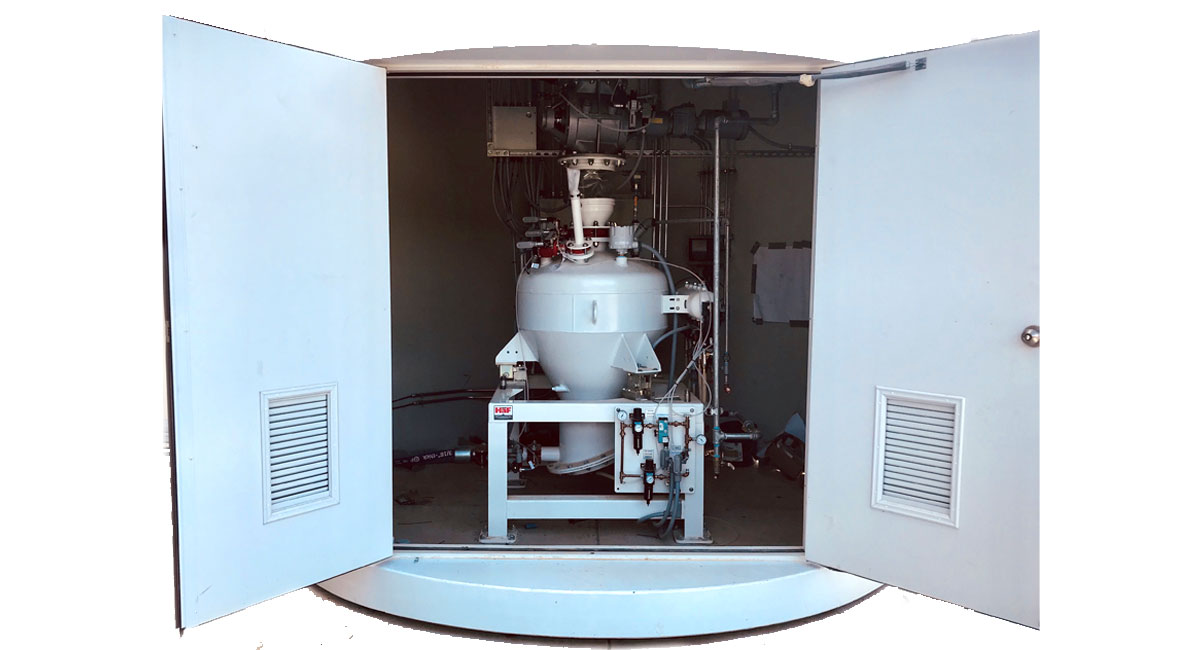

Companies struggle with keeping their material handling equipment clean. especially the inside of the equipment. For example, have you ever tried to clean an industrial-sized mixer, like a ribbon blender? With most industrial equipment, like mechanical mixers, it can be labor-intensive, and dangerous, to ensure the unit is effectively cleaned and that the backsides of all the mixing paddles are clean. The tiny crevices in the design are out of sight but not out of mind. But, what if we told you that you could blend your dry powders without a mechanical-oriented mixer? Imagine a blender that is just as clean and simple as an empty hopper and cone! At HaF Equipment, we have the solution: Pneumatic Blenders!

Using simple compressed air, a pneumatic blender pulses a bubble of air into the centerline of the cone. That air pushes a column of the dry material upward, like taking a core sample or cross-section of the stratified material. As the column of material moves upward, the air expands and accelerates to throw that material into the headspace of the hopper. It is this motion that creates the mixing action.

The motion of the material also creates an aeration effect that creates a fluidized state for the material. When in a fluidized state, the material is free-flowing. So, as that column of material lifts, the remaining material around the side walls freely flows down and replaces the material blown upward. The mixing of powders happens quickly, with no mechanical friction.

When Pneumatic Blending is Best

Pneumatic blending isn’t for all applications, however. It is best when an extremely quick and accurate blend is needed. Since the blending action isn’t a “folding over” or “mass cutting,” the blend is extremely homogenous in a very short period. Rather than a blend measured in tens of minutes, most pneumatic blends can be accomplished in less than a minute. All of this is, however, dependent on the material blended. Material that is easily fluidizable, such as flour, glass bubbles, or powders for ceramics, work extremely well. Materials that are large particles, such as stones or nuts, are not good candidates since the air tends to flow through the material, not allowing the column of material to lift.

Comparing Blender Types

- RIBBON blender.

A Ribbon Blender typically has a U-shaped horizontal trough and then a custom fabricated ribbon agitator that spins to mix powders. The pros to the ribbon blender are that it operates at a cost-effective price point and offers high capacity. Pneumatic blending can also work with large tonnages. Unfortunately, the ribbon blender does not fill all the way and is often left with dead space (unused space). Another downfall to the ribbon blender is that it can be dusty, especially around the mechanical seals. Pneumatic blending is sealed tight and is a simple hopper in concept. The ribbon blender also tends to have a larger footprint and can sometimes damage the product in production. Pneumatic blending is essentially a simple hopper and cone with air pistons in the cone. The pneumatic blender is gentle in regard to damaging product. It uses compressed air, not stainless-steel agitators.

- PADDLE blender. A mixing paddle blender uses a custom fabricated paddle, typically mounted on a shaft, which can be inserted on the shaft end into the end of a motor drive assembly. The paddle blender offers large capacity, with reduced RPM. On the flip side, the paddle blender is not proven to be efficient, and the gearbox located on the top of the vessel can be a hindrance.

- TUMBLER or V blender.

V blenders are rotary mixers, also called tumble blenders. Just like how it sounds, the shape of the machine is a “V”. The V is formed by welding together two cylinders. The whole unit rotates allowing the powders to mix. This is called diffusive (or dispersion) mixing. In diffusive mixing, the particles of solids move randomly, typically rolling down when their container is rotated. The motion is driven by gravity and falling particles. There is no mechanical agitator or ribbon.

There are no agitators inside the V blender, all the movement of the powder comes from gravity and the rotation of the shell. Since there is no agitator, it will perform “ok” with free-flowing solids, but it is less effective with cohesive powders.

The benefit of the V blender is that is has smooth internal surfaces that results in a more sanitary design. But this is the same with pneumatic blending where the inside of the vessel is sanitary smooth.

You get the clean vessel with the pneumatic blender as needed in pharmaceuticals, and the pneumatic blender is ultra-sanitary. The tumble blender tends to be more expensive, offers low capacity, and does an “ok” job with mixing.

Pneumatic Blender

Pneumatic Blender Flexibility – Powders & Liquids

The applications and variations of the Pneumatic Blender are vast and can be used for varying applications depending on the industry. Coatings or flavor additions are a great way to use pneumatic blending with liquids. Pneumatic blenders can also be used for fluidizing silos and aid in silo discharge of ingredient powders.

When the pneumatic blender is put at the bottom of a dense phase conveyor vessel, it can receive the powders in, blend, and dense phase convey the powders long distances. This is extremely helpful when you want to blend powders in a powder dedicated room, and then send the blended batch of powders to a production line elsewhere in the manufacturing facility. This set up is very flexible.

Lastly, this system can utilize inert gas to blend combustible powders.

Summary:

HaF Equipment is here to assist you with which application would benefit from pneumatic blending; and seeing is believing. So, contact a HaF account manager today to see what options we can provide to test the blender. We can do this in our facility with your material, or directly at your facility to give real-time results with as many in-plant conditions as possible. At HaF, we are Ready to Connect!

CONTACT US today to discuss your pneumatic blending equipment needs.

LIKE THIS ARTICLE? PLEASE SHARE.

About HaF Equipment

HaF is a Minnesota-based company with employees spread out across the USA and capabilities world-wide. We’re ready to support your manufacturing industry needs no matter where you live or what type of industry – we’ve got our finger on the pulse Ready to Connect.

For more information about how we can help you meet your goals, don’t hesitate to call us at (651) 653-5098, or complete the Contact Form on our website.