Revenue in the Confectionery & Snacks segments is estimated to amount to US$299.50bn in 2023 and is expected to grow annually by 3.00% (CAGR 2023-2027). Most revenue is generated in the United States. (Statista) As the confectionery and snack manufacturing process continues to expand, driven by America’s love for chocolate bars, doughnuts, marshmallows, and other popular treats, the need for confectionery and candy processing equipment in the market has never been more critical. Manufacturers must adapt to this rising demand by ensuring their snacks and confectionery manufacturing machines can efficiently manage sticky, gooey ingredients without compromising on quality.

America's Sweet Tooth

The demand for sweets and snacks has never been higher, and with the growth of e-commerce and global marketplaces, manufacturers of confectioneries and snacks have had to scale up their operations. To ensure the production of high-quality confections, however, manufacturers must invest in reliable snack manufacturing machines that meet the specific needs of their product line.

The equipment essential for the snack manufacturing process is designed with strict hygiene protocols in mind, ensuring consistent output to maintain flavor and texture standards. Additionally, snack and confectionery manufacturing machinery should be easy to clean and maintain, supporting sanitary conditions and the production of high-quality products.

To maintain consistency in product quality, manufacturers in the confectionery and candy processing equipment market must choose durable machinery capable of enduring extended use. Investing in the right snacks manufacturing machine and confection processing equipment enables producers to maximize efficiency while delighting consumers with their favorite treats.

In addition, manufacturers must also consider food safety regulations when selecting the appropriate equipment. That selection must include equipment designed with food safety standards in mind so that products remain clean and safe to consume. By maintaining these standards throughout production, manufacturers can ensure their customers receive a product they can trust.

Equipment Used to Manufacture Confections and Snacks

The equipment required to manufacture confections and snacks varies depending on the specific production process and may include:

- Mixing equipment: used to blend the ingredients, such as sugar, corn syrup, and gelatin, together.

- Cooking equipment: used to heat and cook the mixture to a specific temperature and consistency.

- Whipping equipment: used to aerate the mixture and create the fluffy texture of the marshmallows.

- Depositing equipment: used to deposit the marshmallow mixture into molds or onto a conveyor belt.

- Cutting equipment: used to cut the marshmallows into desired shapes and sizes.

- Packaging equipment: used to package the marshmallows into bags, boxes, or other containers.

Some manufacturers may also use additional equipment for specific production processes, such as extruders or enrobing machines. Additionally, production equipment for confectioners and snacks may include:

- Bulk Bag Unloaders

- Bag Break Stations

- Blower packages

- Bin vents

- Filter Receivers

- Piping

- Liquid skid/tote

- Extrusion

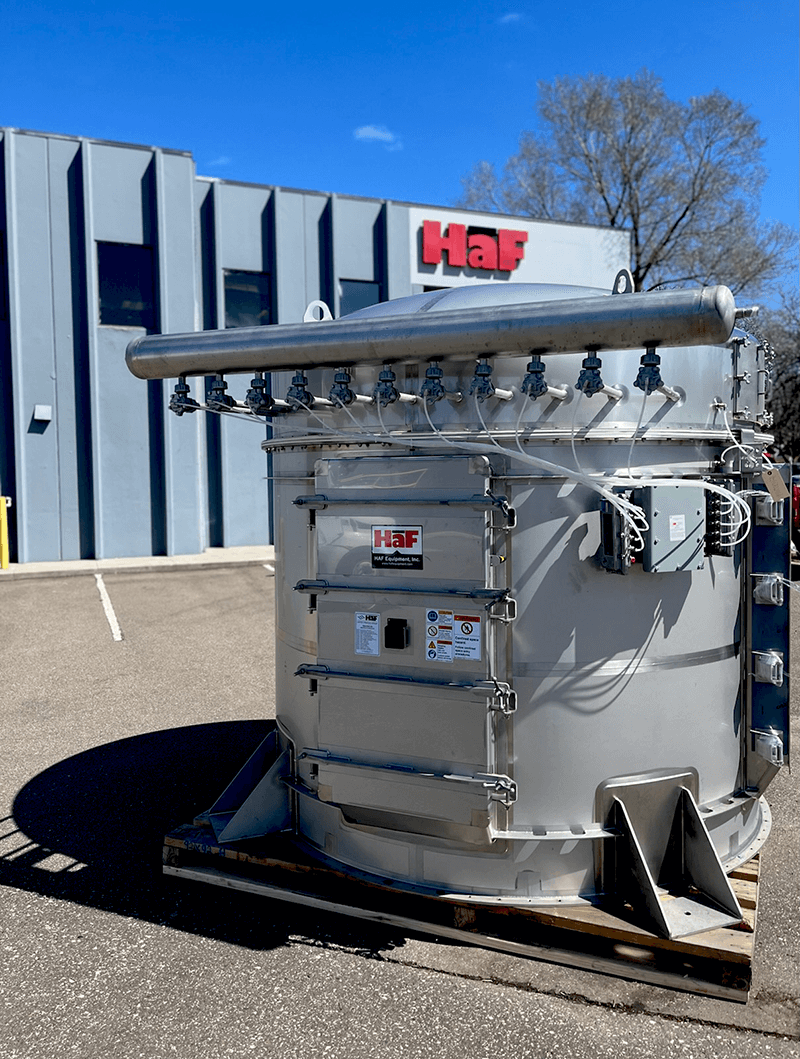

HaF Equipment Does Its Part

Custom-engineered material handling equipment systems are in greater demand now, more than ever. Increasing demand for safe and hygienic processes drives growth within the snack and confection market.

By keeping our finger on the pulse of the industry, HaF Equipment is ahead of the curve. The manufacturing of our equipment focuses on operator-centric designs and our proven processes for success to support our major markets, making HaF Equipment more than just a great equipment manufacturer. We are your partner in excellence, committed to your success through service with integrity, purpose, and ingenuity. By designing innovative solutions to powder handling, bulk material handling, dust collection, and batching systems, we meet today’s manufacturing challenges head-on to break through the status quo.

HaF has the expertise and experience to accommodate a wide range of needs when it comes to material handling and equipment manufacturing. We’re Ready to Connect with you and offer a customized solution and discuss your specific project needs.

Contact a HaF account manager today to explore our customized solutions tailored to your specific snack manufacturing and confection processing needs

You May Also Like:

Soft Drink Production: The Role of Material Handling Equipment

Is Your Industrial Dust Collector Equipment Sufficient?