A Gravimetric Enrobing Feeder Case Study by Michael Thiel (HaF Equipment)

How do you apply a spice blend onto a base piece of product?

How do you evenly coat the product?

How do you get the right amount onto the material?

Adding spices or flavorings to a base product is a foundational aspect of food manufacturing that is critical in many applications. Whether it be coating a potato chip, a chocolate candy, or a piece of cereal, enrobing feeding directly impacts the consumer. I am sure many of us know friends or family that evaluate the coating of a piece of cereal or a potato chip with every bite they take.

Recently, a customer turned to HaF again to provide a feeder that would feed a blend of spice to a piece of base product. The first aspect of the application to evaluate is the customer’s needs. What is the end goal? We connect with the customer first on this level. For this application they required a continuous application of blended spice (a mixture of various sugar powders) at a consistent dosage rate over the range of six to seven feet. The final auger length from inlet centerline to discharge centerline was approximately eight feet.

With this information, the design considerations can begin!

- Powder Flow Characteristics

In this case study, the feeder handled various sugars. These powders attract moisture. While the system can run with un-treated air, it will get messy in a hurry. We recommended and the customer agreed that dry air with a dewpoint of 40 F or lower was to be used for the proper handling of these powders. For example, the vacuum convey system that moves the blended batch from the blender to the filter receiver above the feeder should use dry inlet air. This dry air is also necessary for an aeration of the material and back pulsing of any filter media along with purge seal air. It is important to manage any moisture that can enter the system.

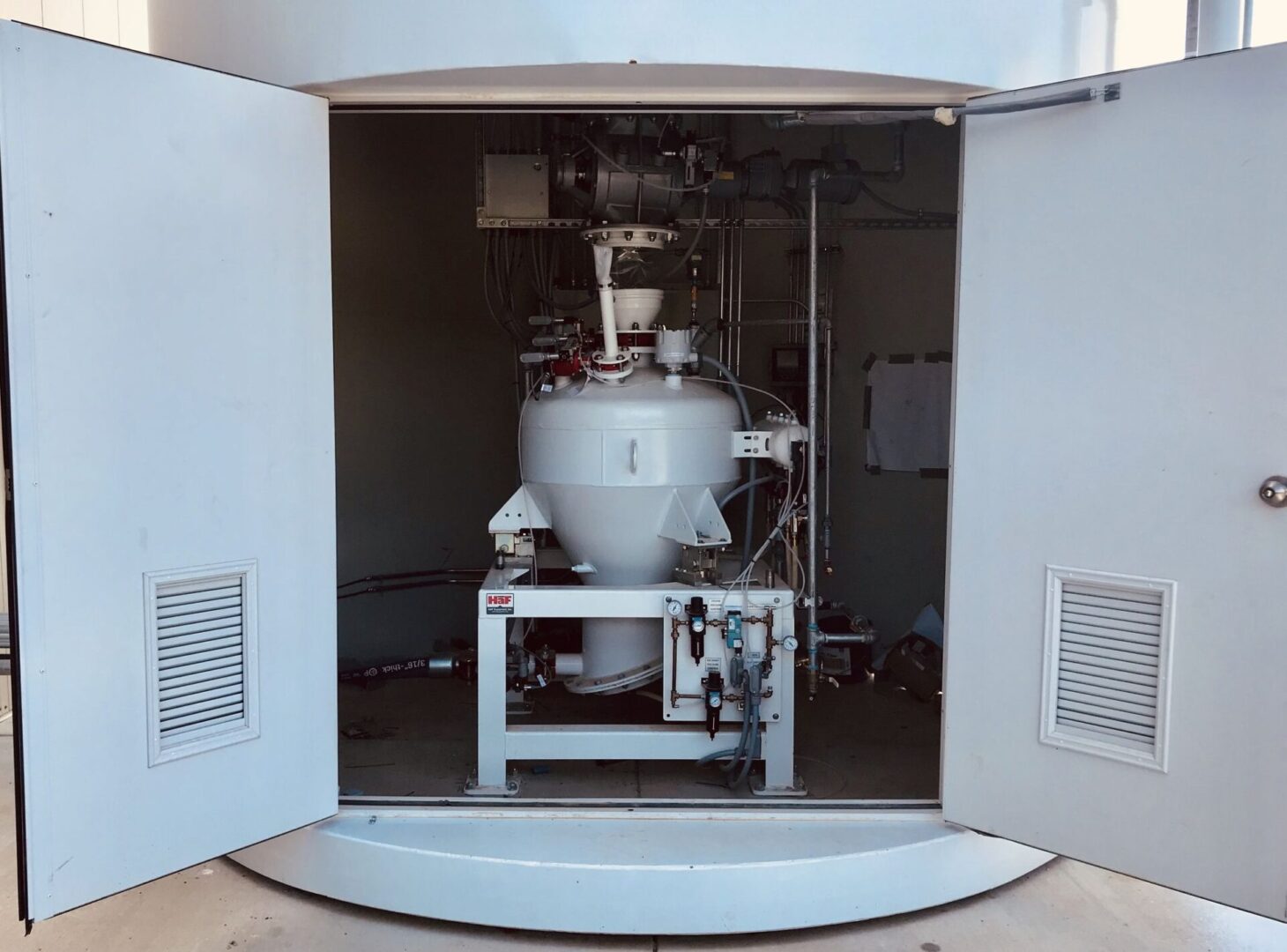

2. Cleanability Design

It is often overlooked how the operator will interact with the equipment once installed and commissioned. At HaF, we follow a strict design philosophy of tool-free, quick take-apart. This design philosophy caters to the food industry where cleanability of equipment is so important. For the enrobing feeder in this case study, HaF used a drop bottom door on the auger that allows the operators to easily rinse out and dry the auger. The auger was also designed with a quick remove housing auger tube to take the feeder apart easily and quickly by any operator.

3. Hopper Sizing

The sizing of the feeder hopper depends on the dosage rate and bulk density of the powder. Then the design consideration to answer is how many refills per hour can the process allow. For example, if the hopper is larger, there will be fewer refills per hour which allows the feeding system to remain in gravimetric mode for a longer period of time, which is important because it allows the feeder to rely on accurate load cell weighing. But a larger hopper requires higher elevation, so there is a balance. On this project, HaF designed the system with an approximate six refills per hour, which drove the sizing of the feeder hopper. For this application a hopper was sized to hold two cubic feet of batch. But the final hopper water fill volume was much larger than this to accommodate necessary surge in the system to have during refills.

4. Auger Style

The auger size and discharge style are of utmost importance. The size of the auger is determined by the dosage rate and bulk density. For example, does the auger need to be 4-inch, 6-inch, or 9-inch? This sizing is often determined through in-house trials and testing. For this application, a 6-inch auger was selected. Next, it is important to connect with the end user to understand what level of adjustability is required. For this application, adjustability was important. The cantilevered auger, which was tool free quick take apart, had an adjustable multi hole distribution on bottom of the discharge tube that could be adjusted to impact the way the powder was applied over the six foot spread.

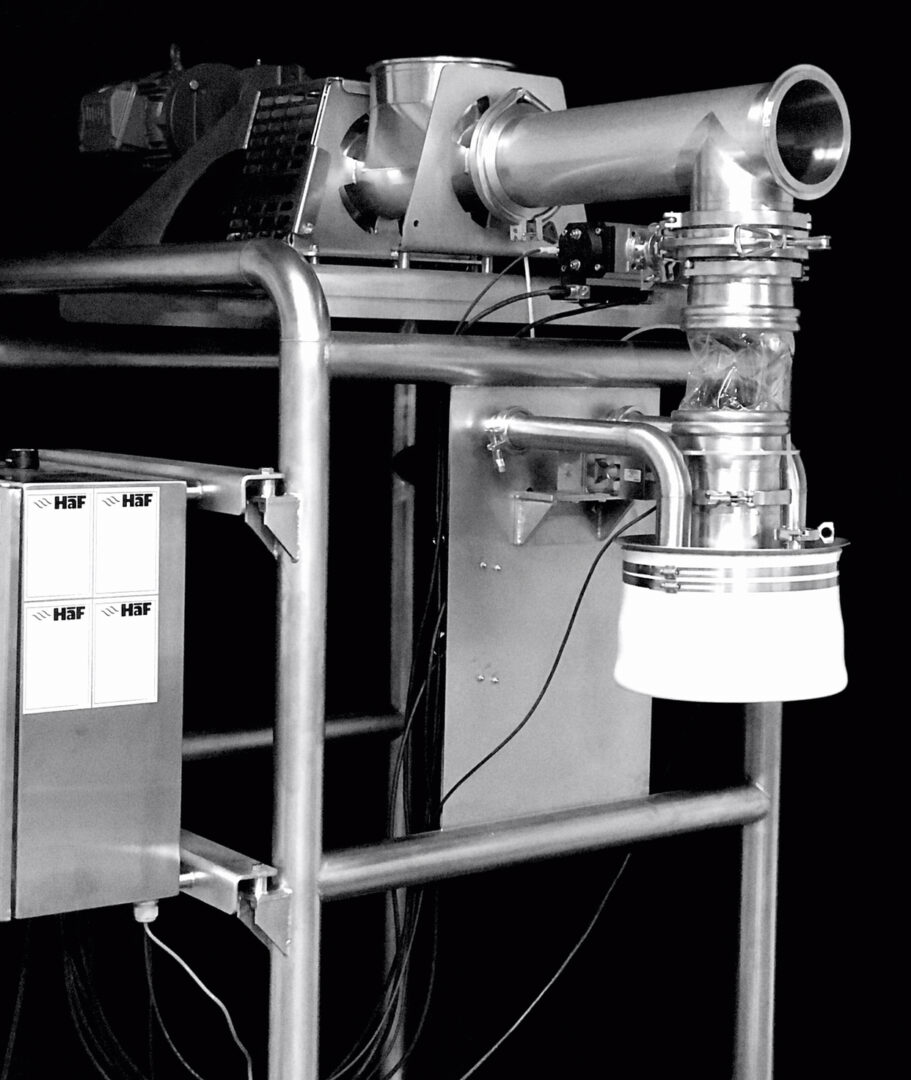

5. Dust Control

No one likes dust. Especially the operator! On this gravimetric enrobing feeder, a bin vent with an exhaust fan was used to pull a slight vacuum on the feeder so as to ensure dust would not leak out any seam on the feeder. This simple design consideration impacts the quality of the work environment of the operator for many years.

6. Feeder Control

Lastly, it is important to understand what level of control the end user requires. In some cases, a volumetric feeder is all that is required, meaning, the auger is controlled using a pre-set correction curve where motor speed correlates to the customer dosage rate setpoint. But in this case study, the gravimetric feeder was requested. In this case, the feeder is on load cells and is controlled by a gravimetric controller. Gravimetric feeding gives a perfect ratio of pounds of spice to pounds of base being coated. When the base rate varies, the gravimetric feeder speeds up or slows down accordingly, and is constantly checking the actual dosage rate via the load cells. This type of continuous gravimetric feeding reduces waste and provides a more consistent coating on the base product.

Every application is unique, so the most important aspect of any project is to connect with the end user. Communication is critical. We are ready to help. Contact HaF for your enrobing feeder projects ([email protected]).