Authors: Sarah Wagner and Hunter Kloes

Long before the soda industry brought us drinks as a refreshment, pharmacists prescribed “soda pop” to patients. Initially, pharmacists served carbonated water at the pharmaceutical counter to patients for medicinal purposes. Soft drinks were not limited to the medical industry, however. They were also commonly accepted to drink with dinner.

By 1820, flavoring was added to carbonated beverages – from salt to ginger. In 1830, soft drink producers started adding lemon; by 1858, they added tonic. Yet, it wasn’t until 1886 that John Pemberton, a pharmacist in Atlanta, Georgia, invented the first cola drink.

John Pemberton was a chemist and druggist before serving in the Civil War. During the war, Pemberton suffered a major wound and became dangerously addicted to the pain reliever morphine. To defeat his dependency on morphine, Pemberton created Coca-Cola. He heard another doctor used coca (cocaine) to cure opium habits; Pemberton combined the coca leaves with kola nuts. His bookkeeper convinced him to call it “Coca-Cola.” Nearly 140 years later, soft drinks make up over a $430 billion industry. (Grand View Research)

Steps in Soft Drink Production

- Water Treatment. Flocculation is the process where solids form larger clusters, or flocs, for removal from water. Aluminum sulfate and ferric chloride are examples of what’s pulled. Monochloramine is used to kill germs, yet it is still safe to drink.

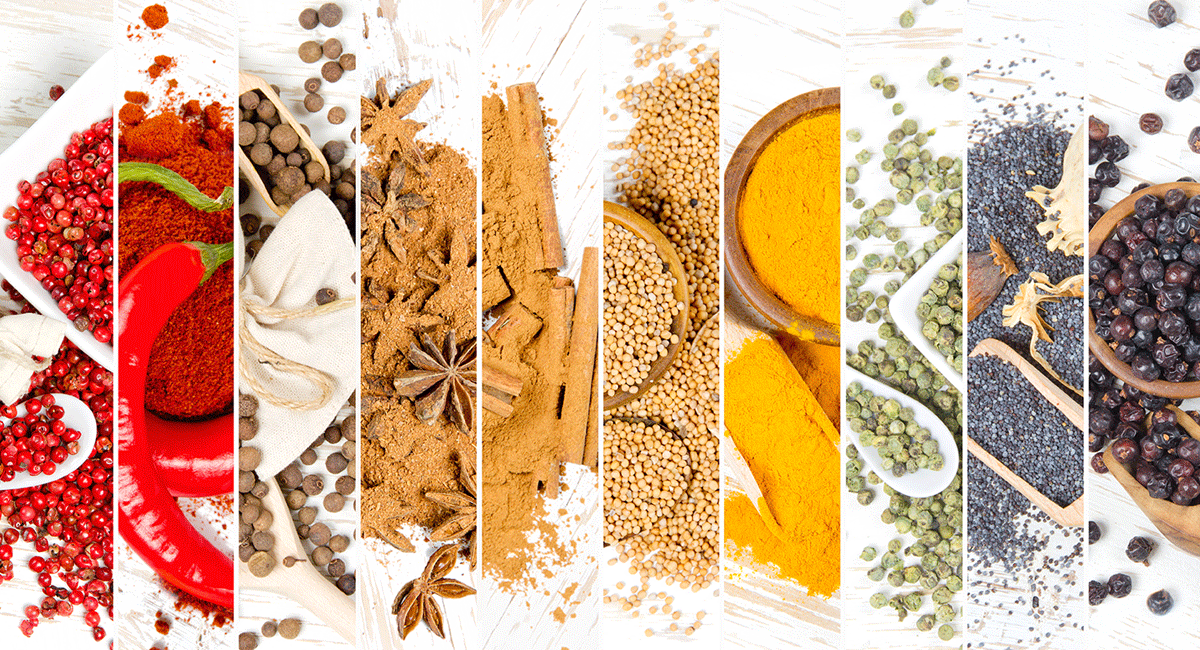

- Extraction of Raw Goods. Raw materials for producing goods and services may include vanilla bean, apricot seed, and lemon. An example of extraction used in soft drinks is the brand, Dr. Pepper. It contains extract of cherry, licorice, amaretto, almond, vanilla, blackberry, apricot, caramel, pepper, anise, sarsaparilla, ginger, molasses, lemon, plum, orange, nutmeg, cardamom, allspice, coriander juniper, birch, and prickly ash. Whew!

- Sugar or High Fructose Corn Syrup (HFCS) Handling. Sugar is extracted from beets, corn, and cane. Raw goods are then mixed with the sugar sludge. The concentrate is typically made at the soft drink plant headquarters using a variety of ingredients like those listed above.

The Role of Material Handling Equipment

in Soft Drink Production

Soda production is a complex process requiring sophisticated material-handling equipment to ensure efficient processing and production. To produce high-quality soda, raw materials such as sugar, yeast, and water must be loaded into equipment designed to manage the ingredients for further processing. This includes specialized machines for weighing, blending, and pasteurizing the ingredients in a precise manner.

Then, additional soda manufacturing equipment is needed to move the processed material from one station to another within the facility. For instance, conveyors are often used during storing and transporting bulk materials like sugar that need to be directed onto other processing equipment with little manual labor involved. Robotic arms are also commonly used to automate assembly lines, while pallet jacks can help streamline loading processes at different stages of production.

Sanitary Design in Soda Manufacturing

The importance of sanitary equipment design in soda manufacturing cannot be overstated. The demand for safe food and beverage products has never been greater, and sanitary equipment is essential to meet these requirements. Sanitary equipment design involves using materials, components, and methods that eliminate contamination risks during production. This includes using hygienic surfaces, minimized crevices, effective drainage systems, and avoiding cross-contamination between different production steps.

Choosing the Right Soda Production Manufacturing Equipment

Quality control protocols must be implemented when choosing soda production and manufacturing equipment to ensure all materials used meet health standards and minimize potential hazards associated with the production process itself. In addition, all components should be easy to clean and maintain while being corrosion-resistant from any liquid or chemicals used during the manufacturing process.

When it comes to soda manufacturing, there is no room for shortcuts. The selection of the right soft drink manufacturing equipment is essential in ensuring a safe, efficient, and profitable operation.

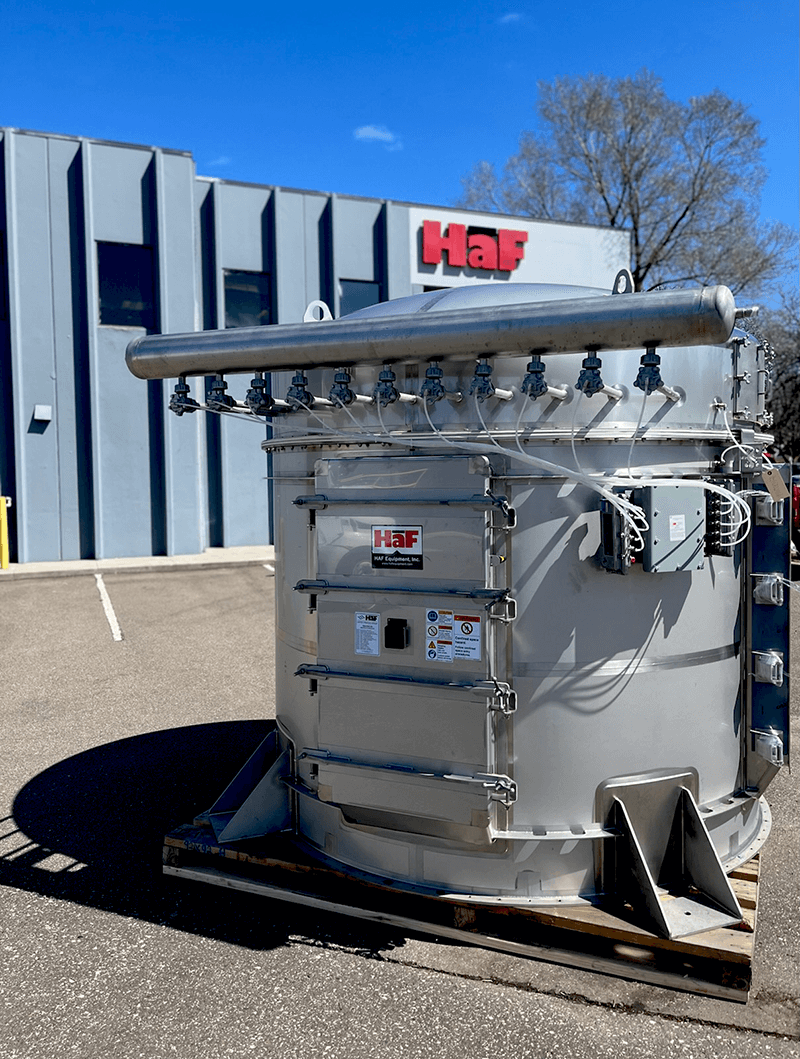

At HaF Equipment, we understand that the quality and performance of your process equipment can determine the success or failure of your business. That’s why all of our products are designed to meet and exceed industry standards while providing maximum efficiency and reliability. Our team has decades of experience engineering high-quality solutions that have been tested and proven to perform in challenging manufacturing environments.

Contact a HaF account manager today to discuss your options.

You May Also Like: