by Becca Hansen and Kim Selle

Industrial dust collection system in manufacturing is vital to workplace safety. In 2021, there were 51 dust-related fires worldwide, resulting in five injuries. Twenty-five (25) of these fires were in food production facilities. Much like the severity of fires, explosion mitigation is a top concern. In 2021, there were twenty-eight (28) dust-related explosions worldwide, resulting in 39 injuries and 8 fatalities, 10 of which were food product-related. In a facility, there are many elements present for a dust explosion or fire to occur: fuel, confinement, dispersion, oxygen, and a spark. An effective and properly operating industrial dust collector and dust collection system minimizes the risk of fire or explosion.

In addition to fire and explosion prevention, there are several other reasons to incorporate industrial dust collection and the right industrial dust collector into manufacturing systems. In the United States, OSHA requires dust control in indoor workplaces to comply with legal limits for each ingredient and material. Additionally, effective dust collection and control assists with eliminating cross-contamination of food or other materials; control of health hazards, including bacteria, allergens, and, yes, insect parts. It can also assist with efficiency and recycling or reuse of food scraps, food-grade material, or pet food. Having an industrial dust collection system creates an overall cleaner work environment by keeping dust and particles from getting into the air and keeping it away from the operator.

Depending on the industry and application, the dust properties will affect which industrial dust collection equipment is best. Some of these properties include:

- Particle size (small or large)

- Bulk density (loose or compact)

- Composition (acidic or basic)

- Temperature (room temperature or elevated)

- Moisture level (low or high)

Selecting the correct industrial dust control equipment to handle the dust is critical and will depend on the product and its handling in the system.

Dust Collection Methodologies

HaF Equipment offers custom design dust collection systems in any of our three general methodologies:

- Dry Dust Collection

- Wet Dust Collection

- Portable Dust Collection

Dry Dust Collection

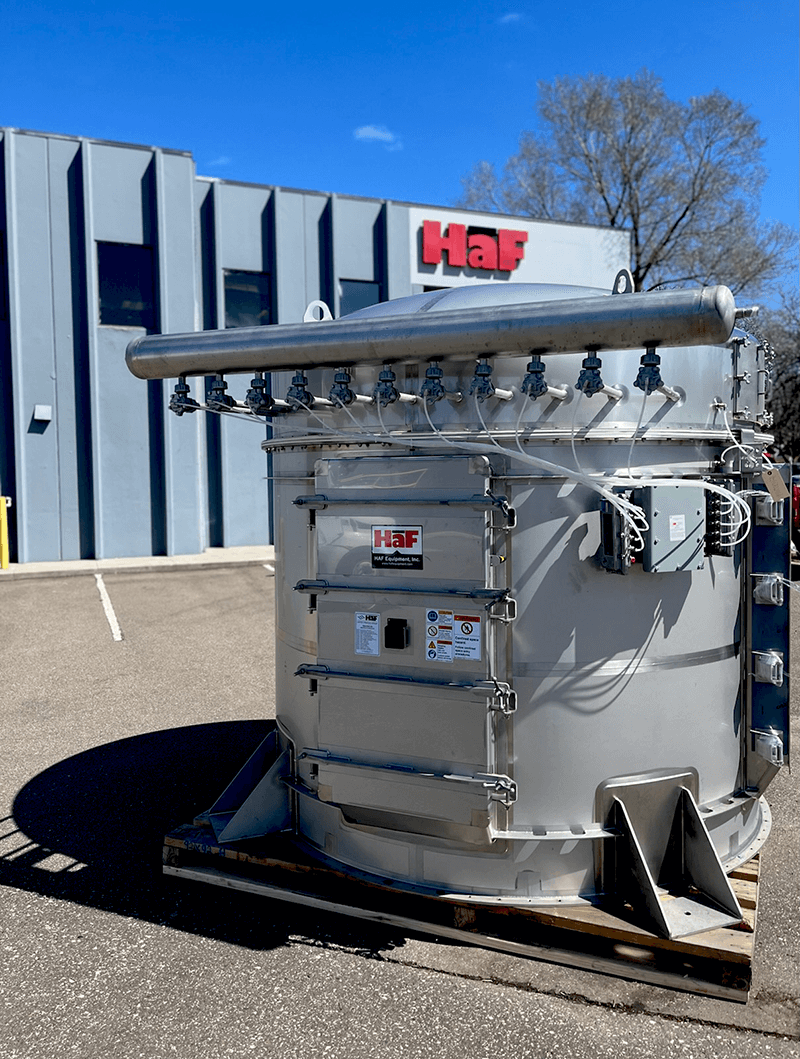

HaF utilizes envelope-style filter bags to provide maximum filter area in a small space, This accommodates the custom-sized airflow for the application, and the dry dust collector captures dust particles on the filter bags.

With HaF’s reverse jet pulse cleaning system, the filter bags drop dust into a hopper that can be manually or automatically removed.

Wet Dust Collection

Our wet dust collector utilizes a turbulent zone of water to capture dust particles. This method is a great way to eliminate explosion mitigation equipment, and it is easily cleaned with an optional Clean In Place (CIP) design. The dusty water discharges with either a manual process or automated valving. Wet dust collection also removes the requirement of filter bags altogether.

Portable Dust Collection

A portable dust collector allows the operator flexibility to move the dry dust collector to the point of use. Our portable dust collector comes with many customizable features including dust removal systems.

Pick-up points can be designed for each method including custom hood designs. We then size the ductwork and corresponding exhaust fan for an exact fit.

Dust Hoods are used in applications where a customer might want to squish the air out of a bag before entering the bag sealing process. There is an overhanging open duct in this application where a vacuum is being pulled. Dust hoods can also be used over conveyors to prevent dust from being spread throughout the plant.

Summary:

Dust collection is a critical step in the manufacturing process. By collecting dust before it has a chance to enter the atmosphere, dust collection systems help to keep the air clean and safe to breathe. In addition, dust collection systems help to prevent the spread of dust particles throughout the factory, which can lead to equipment malfunctions, production delays, and worse, plant explosions. By investing in high-quality dust collection systems, manufacturers can help to protect both their workers and their bottom line.

HaF Equipment is here to assist you with which dust collection application and equipment would benefit your business.

Contact a HaF account manager today to discuss your options for an industrial dust collection system.